For this week's Script Tip Friday, Fabio Pavia, PhD, MBA Senior Product Manager at Ansys, discusses how you can design for an optimal mould shape in 3 steps using partner tools for composites connected to Ansys Mechanical.

The presence of spring-in effects and cure-induced distortions is a frequent issue encountered while manufacturing composites parts through techniques likes resin transfer molding of thermosets or injection molding of thermoplastics materials.

Traditionally expensive and time-consuming experimental trial and error methods are used for designing an optimal mould shape, so to minimize such undesired deviations from the desired shape of the composite parts. In fact, these irreversible warpage distortions during manufacturing are detrimental to the assembly and then to the mechanical integrity of the part.

The robust Ansys solver technologies enable designers to study and quantify the presence of unwanted residual deformations in relation to the process simulation of reinforced and unreinforced plastics manufacturing realized within many of the partner tools for composites connecting to Ansys Mechanical (for example, ACCS, Moldex3D, Moldflow, SigmaSoft, CadMould). In addition, an optimal mould geometry can be determined by numerical simulation using the geometric capabilities of the SpaceClaim morpher using the residual deformation available from Ansys Mechanical: this procedure easily helps producing composite components directly matching the nominal target designing without the need of expensive experimental tests.

Mould compensation and validation can be realized in 3 easy steps (shell or solid geometries can be used for the mould):

1

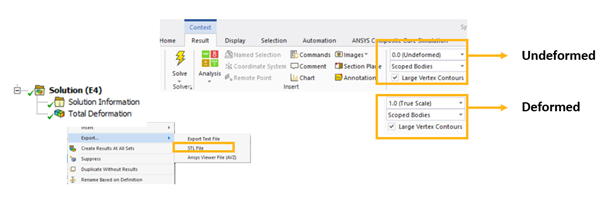

The undeformed and deformed (uncompensated with warpage deformations) mesh of the mould can exported directly from Ansys Mechanical as STL files:

2

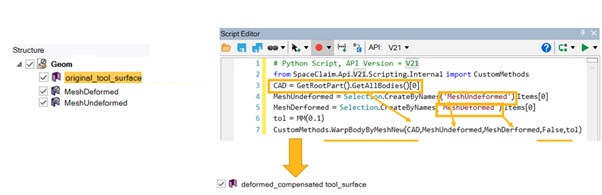

The Ansys SpaceClaim morpher can be accessed through a simple script after importing into Spaceclaim the original CAD of the undeformed mould (to be morphed at its optimal shape) and the STL meshes (undeformed and deformed) exported from Ansys Mechanical. The script shown below will directly use the morpher to shape the nominal mould geometry given the residual deformations predicted for the specific manufacturing process:

3

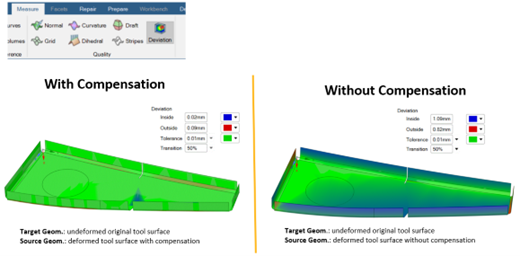

The Deviation tool within Ansys SpaceClaim can be used to measure the deviaton with respect to the nominal / desired shape when repeating the manufacturing process with the compensated mould shape obtained before using the morpher (in this case a flange for earospace applications is shown, process induced effects due to curing are studied through ACCS):