It's Friday again which can only mean one thing... time for a new Script Tip. Our favorite Senior Principal R&D Engineer, Pierre Thieffry, is back to talk about Bolt Pretension. Enjoy!

"What if you could easily create your own parameters in Mechanical using simple scripts to run design variations and optimization?

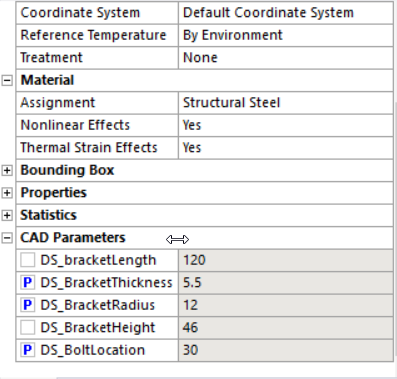

Parametric variations are part of Ansys Mechanical’s DNA. Back in the times where structural simulations were created by scripts, we used (and still use!) the APDL language. And APDL means Ansys Parametric Design Language. Talk about DNA! The Mechanical interface that most people use today also embeds an easy way to create parameters. Wherever a parameter can be defined, you’ll see a small white box. Check that box et voilà, the parameter is created, indicated by a blue “P” in the check box. Many parameters are available, from CAD dimensions to load amplitudes, material properties and of course simulation results. All of this creates input parameters (design variables) and output parameters (performance indicators) that can be used in a in-depth analysis of your design using tools such as Optislang.

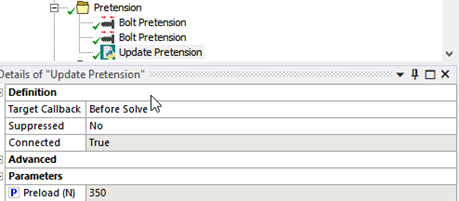

Yet not all items can be parameterized and there are times where you will want to create your very own parameters. Scripting in Mechanical allows you to do this easily. Since 22R1, the Python Code objects allow you to embed Python script in the simulation tree so that the script gets executed every time the model is updated. The object supports the definition of properties, some of which can be then parameterized. In the example below, you see a Python Code designed to update multiple bolt pretensions at once. The object in the tree has the famous white box and its “P” indicator and the script below shows you how this parameter is used. You first retrieve its value then update all Bolt Pretension items with this value. As simple as this!"

If you're sill not convinced about the benefits of scripting, you definitely should check this great article: Blade Fatigue Assessment at Bewind Is a Breeze