This article is brought to you by Sotirios Kakaletsis. You can find out more about his research on his website and contact him via his LinkedIn.

Introduction

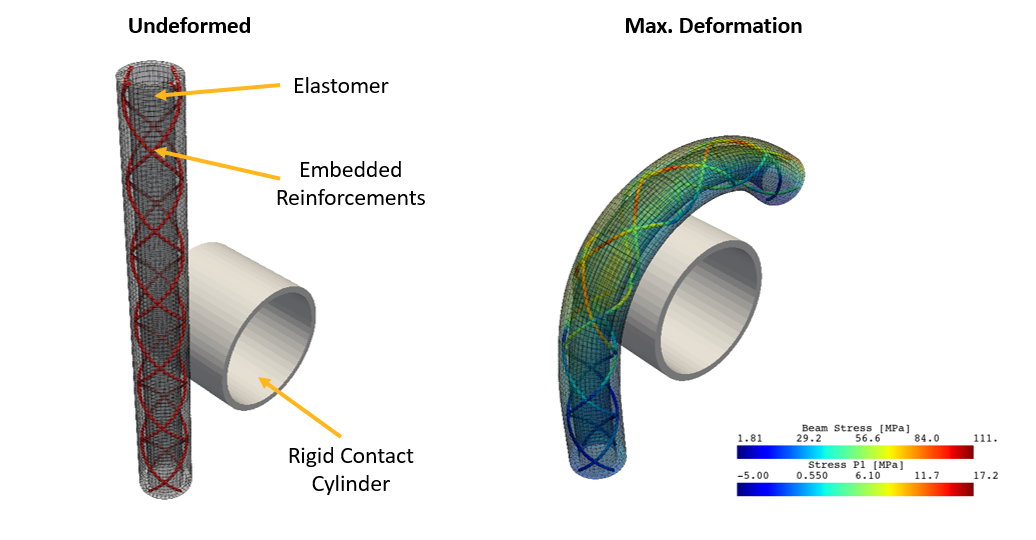

In this article, we explore the mechanical behavior of a flexible, biomedical catheter under large deformation. Using the scripting capabilities of PyMAPDL, we perform an iterative analysis to evaluate the apparent flexural rigidity of the catheter under different design configurations.

The Catheter

We model a braided biomedical catheter as a reinforced elastomer. For the elastomer we use the incompressible neo-Hookean (rubber-like) material model, whereas the reinforcements are much stiffer, linear elastic beams.

Through embedding stiff reinforcements we aim to achieve the required axial, flexural and torsional rigidity, as described -for example- in the case of cardiovascular catheters (J. Carey et al., 2004).

Within the scope of this example, we will focus on the apparent flexural rigidity measured as the reaction bending moment of the catheter, while it wraps around a rigid cylinder (see following figure).

The Pipeline

Via a main script and for each set of design parameters, we iteratively call the function Run_Catheter() that formulates the MAPDL model and runs the corresponding simulation. Once the run is complete, we call the post processing scripts Plotter() and Animator() to visualize the stress fields of the elastomer and the reinforcing beams.

Step 1: Define basic model input

We first define the basic model input parameters, such as the dimensions, the boundary conditions and the design parameters to be explored. In this case, we focus on the coil angles, expressed as the number of complete loops the reinforcements form over the length of the catheter.

# Basic Model Input

mdl_name = 'HelixAngleStudy'

Ra = 0.6 # Inner Radius

Rb = 0.9 # Outer Radius

Rm = (Ra+Rb)/2 # Coil Radius

H = 15 # Height of catheter

n_cables = 4 # Number of coil-reinforcements

hs = 0.15 # Solid Element length

hb = 0.20 # Beam Element length

# Define Boundary Conditions

ActiveBCs = {'UxAct':False, 'UyAct':False, 'UzAct':False, 'RxAct':True, 'RyAct':True, 'RzAct':True}

BoundaryCond = {'Ux':0, 'Uy':0.0, 'Uz':0, 'Rx':0 , 'Ry': 1.5*np.pi/2,'Rz':0}

BoundaryCond.update(ActiveBCs)

# Full loops for each coil-reinforcement

helix_angles = np.array([1,2,3,4,5,6,7])*2*np.pi

Step 2: Perform the analysis

In the main script again and following the definition of the input, we initialize the MAPDL session. Next, for each value of helix angle, we perform a simulation of the bending problem. The output and the quantity of interest in this case is the reaction bending moment as a function of the prescribed, rotation angle.

# Initialize MAPDL

path = os.getcwd() # Get current working directory

path = path +'/'+mdl_name

isExist = os.path.exists(path)

if not isExist:

# Create a new directory because it does not exist

os.makedirs(path)

mapdl = pymapdl.launch_mapdl(run_location=path, nproc=6)

# Helix Angle Study

TotUF = [] # Reaction forces & Displacements

for idx, helix_angle in enumerate(helix_angles):

fl_name = mdl_name + str(idx)

U_F_ = Run_Catheter(mapdl,fl_name,Ra, Rb, Rm, H, n_cables, helix_angle, sol_el_size=hs, beam_el_size=hb, BCs = BoundaryCond)

U_F_['CoilAngle'] = helix_angle

U_F_['n_cables'] = n_cables

TotUF.append(U_F_)

#Save in each iteration, just in case

f = open('./' + mdl_name + '.pkl', 'wb')

pickle.dump([hs, hb, TotUF], f)

mapdl.exit()

Intermediate steps: Building the model

As we mentioned previously, within our framework, the main script calls the function Run_Catheter() which builds and runs each simulation, separately.

As a first step, we define the two material types, one for the elastomer and another for the reinforcements.

#--------------- MATERIALS---------------------------

# Define Base material

D1 = 1 / (C10 * k_mu_ratio) # for nearly incompressible neo-hookean

mapdl.tb('HYPER', mat=1, tbopt='NEO')

mapdl.tbdata(stloc=1, c1=C10, c2=D1)

# Define Beam material

mapdl.mp("EX", 2, Eb) # Elastic modulus

mapdl.mp("DENS", 2, 7800) # Density in kg/m3

mapdl.mp("NUXY", 2, beam_nu) # Poisson's RatioIn the same function, next we define the various solid geometries, (cylinders), and the corresponding contact surfaces. Note, that this process involves defining local coordinate (cylindrical) systems, to accommodate for the different solid orientation, as follows:

#-------------- GEOMETRY -----------------------------

# Create Elastomer Cylinder

vnum0 = mapdl.cylind(Ra, Rb, 0, H)

mapdl.et(1, 185, kop2=0, kop6=1) # SOLID185 C3D8H

mapdl.esize(sol_el_size)

mapdl.type(1) # Sets type1 to subsequent meshing scheme

mapdl.mat(1) # Set the material to neo-Hookean

mapdl.vsweep(vnum0)

# Define Contact Elements

mapdl.starset('cid',3)

mapdl.r('cid')

mapdl.real('cid')

mapdl.et('cid', 174)

mapdl.seltol(1e-12)

mapdl.local(10000, 1)

mapdl.nsel('S','LOC','X', Rb)

mapdl.type('cid')

mapdl.esurf()

# Create Contact Cylinder (Rigid)

Rcyl = 2.5* Rb

Lcyl = 4 * Rb

XC = (Rb + Rcyl)

YC= -0.5 * Lcyl

ZC = H / 3

mapdl.wplane(-1, XC, YC, ZC, 2 * XC, YC, ZC, XC, YC, 0)

mapdl.csys(4) # Change coordinate system to global one

vnum1 = mapdl.cylind(0.9*Rcyl, Rcyl, 0, Lcyl)

mapdl.et(10, 185, kop2=0) # SOLID185 C3D8H

mapdl.esize(0.25)

mapdl.type(10) # Sets type1 to subsequent meshing scheme

mapdl.mat(1) # Set the material to neo-Hookean

mapdl.vsweep(vnum1)

mapdl.wpcsys(-1, 0)

mapdl.csys(0)

# Define local coordinate system to define contact surface

mapdl.starset('tid', 4)

mapdl.r('tid')

mapdl.et('tid', 170)

mapdl.local(1000, 1, XC, YC, ZC, 0, 90, 0)

mapdl.nsel('S','LOC',"X", Rcyl)

mapdl.type('tid')

mapdl.esurf()

mapdl.local(1, 0)

mapdl.csys(0)Next, we analytically define the topology of the reinforcements, using the general formula x = cos t, y = sin t, z = t, where t is the curve parameter, by generating keypoints and lines on the helical domain.

for i in range(0, n_to_iter):

ang_offest = n_on_radi[i]

if (i%2)==0:

coil_dir = 1

else:

coil_dir = -1

for x in helix_pnts:

cnt = cnt + 1

mapdl.k(1000 + cnt, Rm * np.cos(coil_dir*x+ang_offest), Rm * np.sin(coil_dir*x+ang_offest), c * x)Subsequently, we issue the eembed command to embed the beam elements in to the solid domain

# Create reinfocement ellements

mapdl.esel('all')

mapdl.run("eembed")Within the Run_Catheter() function we also define the boundary conditions, at the free end of the catheter using a remote point rigid constraint.

# Right Edge

mapdl.type('cid')

mapdl.real('cid')

mapdl.nsel("S", "LOC", "Z", H)

mapdl.esurf()

mapdl.seltol() #Set to default

# CreateTarget elements

mapdl.type('tid')

mapdl.mat('cid')

mapdl.real('cid')

mapdl.tshap('pilo')

IDn = mapdl.n('', x=0, y=0, z=H)

mapdl.en(999999, IDn)

mapdl.tshap()

#------ BCs: Rigid displacement on the other end -------------

if BCs['UxAct']:

mapdl.d(IDn, "UX", BCs['Ux'])

if BCs['UyAct']:

mapdl.d(IDn, "Uy", BCs['Uy'])

if BCs['UzAct']:

mapdl.d(IDn, "UZ", BCs['Uz'])

if BCs['RxAct']:

mapdl.d(IDn, "ROTX", BCs['Rx'])

if BCs['RyAct']:

mapdl.d(IDn, "ROTY", BCs['Ry'])

if BCs['RzAct']:

mapdl.d(IDn, "ROTZ", BCs['Rz'])The next intermediate steps in the same function include setting up and calling standard MAPDL solver commands.

For the last step of this script, we visualize the stress fields of the solid domain, using the PyVista library, in the C_Plotter() function. An important point here is to render the 3D beam profiles as tubes, using the respective function.

# Apply the tube filter to beams

pl.update_coordinates(xyz['beam'], mesh=BeamGrid)

beam_grid_srf = BeamGrid.extract_surface()

beam_line = beam_grid_srf.tube(radius=beam_radius)

pl.add_mesh(beam_line, scalar_bar_args=sargs)

Summary and Outlook

The next figure summarizes the findings of our analysis. Our pipeline identifies a range of helix coil angle (or equivalently, the coil pitch) for which the reaction bending moment is minimized. Following the same procedure, the PyMADPL user can optimize other features as well, including stiffness ratio, reinforcement density, various materials.

Overall, the PyMADL framework provides the user with many powerful tools, such as incorporating external libraries, run scripted analyses, generating custom visualizations.